5 Mistakes to Avoid When Cutting LED Light Strips

Whether you’re looking to spruce up your living space, create a mood for your next party, or just add a touch of pizzazz to your latest crafting project, LED light strips are the way to go. They’re versatile, energy-efficient, and easy to install. But before you get too excited and start snipping away at your brand-new LED light strip, there are a few things you need to know.

Cutting LED light strips requires a certain level of finesse and know-how. One wrong move, and you could end up with a mess of tangled wires and wasted money. In this article, we’ll go over 5 common mistakes to avoid when cutting LED light strips, so you can achieve the perfect cut every time. From measuring mishaps to bending blunders, we’ve got you covered.

So, before you grab your scissors and dive in, let’s make sure you know what you’re doing.

When approaching any LED strip project, it’s essential to prioritize accuracy and follow the designated cut lines to ensure flawless cuts every time. Additionally, utilizing the appropriate cutting tools like a specialized cutter can help avoid common installation mistakes that lead to non-functional strips post-cut, ultimately maximizing your lighting effect.

5 Mistakes to Avoid When Cutting LED Light Strips: Mistake #1 – Not Measuring Properly

One of the most common mistakes people make when cutting LED light strips is not measuring them properly. It might seem like a simple task, but even the slightest miscalculation can throw off your entire project. Before you start cutting, take the time to measure your LED light strip accurately.

First, determine the length of the area where you want to install the LED light strip. Use a measuring tape or a ruler to get an accurate measurement. Make sure to measure the entire length, even if you plan on cutting the LED light strip into smaller sections. You don’t want to end up with a strip that’s too short or too long for your intended purpose.

Mark the measurement on the LED light strip. You can use a pencil or a piece of tape to mark the spot where you need to cut. Double-check your measurement to make sure it’s accurate before you start cutting. You don’t want to cut too much or too little, or you’ll end up wasting time, money, and energy.

Finally, use a sharp pair of scissors or a sharp utility knife to cut the LED light strip. Make sure to cut in a straight line and avoid any jagged edges.

Also read: What is the dimension of LED strip light?

To achieve a flawless installation of your LED strip lighting, always ensure your measurements are precise before making any cuts. Avoiding common strip lighting mistakes, like inaccurate measurement or using inappropriate tools, will enhance your lighting projects, leading to a great lighting option that meets your desired lighting effect.

Avoiding Mistake #2: Cutting in the Wrong Place

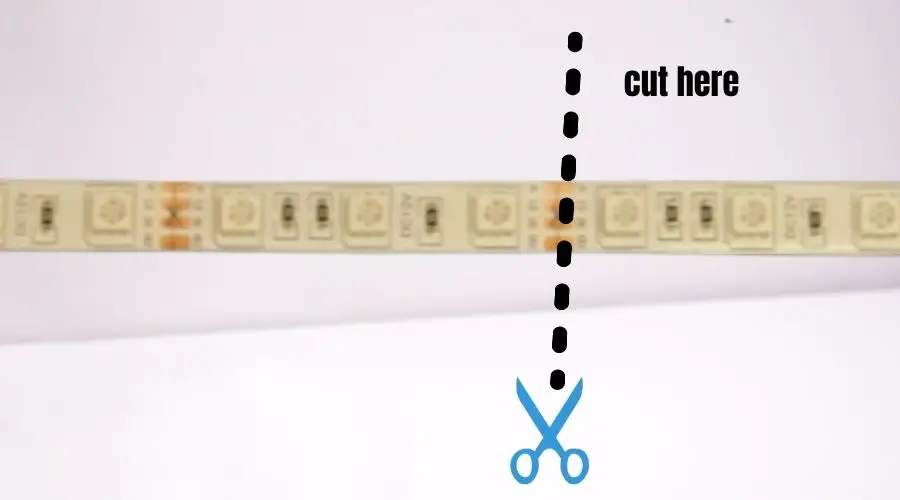

Another common mistake people make when cutting LED light strips is cutting them in the wrong place. This mistake can cause irreversible damage to your LED light strip and render it unusable. Before you make any cuts, it’s essential to know where to cut your LED light strip.

LED light strips are designed with a dotted line in the middle that indicates where you can safely cut them. This line is where the copper contacts are located, and it’s essential to avoid cutting through them. If you miss through the contacts, you’ll break the circuit, and the LED lights won’t work.

To avoid cutting in the wrong place, locate the dotted line on your LED light strip. This line is typically marked with scissors or a knife icon, and it’s usually located every few inches on the strip.

Before proceeding with your LED strip projects, always ensure you are familiar with the unique cutting requirements of your specific strip lights. This careful preparation can help prevent common post-cutting issues and ensure you achieve a clean cut that enhances your overall lighting effect.

Avoiding Mistake #3: Using the Wrong Tools for Your Project

Using the wrong tools to cut LED light strips is another mistake that people often make. Using the wrong tools can damage the LED light strip, create uneven edges, or even cause harm to yourself. Before you start cutting, it’s important to make sure you have the right tools on hand.

When it comes to cutting LED light strips, a sharp pair of scissors or a sharp utility knife is the best tool to use. Avoid using dull scissors or knives, as they can crush the LED light strip and cause it to malfunction. Additionally, using a saw or a rotary tool can generate too much heat, damaging the LED light strip.

Using the right tools is crucial for getting clean cuts when working with LED strip lights. By ensuring you have sharp scissors or a fine-edged cutter on hand, you will help prevent jagged cuts and maximize the overall brightness of your customized lighting solution.

Common Mistakes: Not Sealing the Cut Ends

Sealing the cut ends of your LED light strip is crucial to preventing corrosion and damage. Leaving the cut ends of the LED light strip exposed can cause moisture and debris to accumulate, which leads to corrosion and damage to the LED light strip.

To seal the cut ends of your LED light strip, you can use heat shrink tubing or electrical tape. Heat shrink tubing is a thin, heat-sensitive material that shrinks when heated with a heat gun, creating a tight seal around the cut end of the LED light strip. Electrical tape can also be used to seal the cut end, but it’s not as durable as heat shrink tubing.

Also check out: Best Double-Sided Tape for LED Light Strips

Sealing the cut ends of your LED tape lights is not just essential for preventing damage; it also significantly contributes to the overall longevity and efficiency of your light source. By employing heat shrink tubing or electrical tape, you ensure that the ends are protected, thereby enhancing the light output and helping avoid common strip light mistakes.

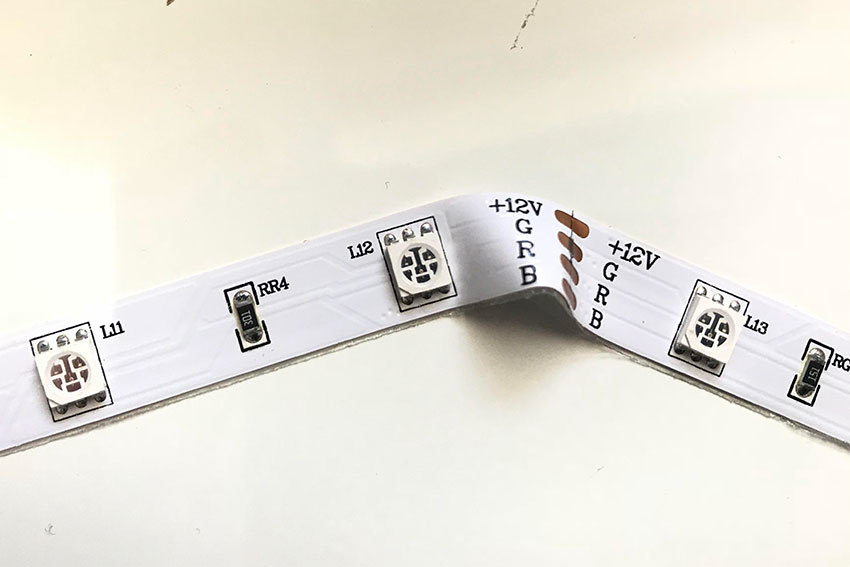

Overbending Strips: Mistake #5 to Avoid in Your Project

Another common mistake when cutting LED light strips is overbending them. LED light strips are designed to be flexible, but overbending them can cause the strip to break or the LED lights to malfunction.

To avoid overbending your LED light strip, it’s important to understand its bending radius. The bending radius is the minimum radius that the LED light strip can be bent without damaging it. You can find the bending radius in the manufacturer’s instructions.

When bending your LED light strip, make sure to bend it slowly and carefully. Avoid bending it sharply or at an extreme angle, as this can cause damage to the strip. If you need to make a sharp bend, use a bending tool to make the bend more precise and avoid overbending.

To prevent your LED strip from becoming useless, avoid common errors such as overbending and ensure you respect the designated cut points. For successful future cuts, always double-check your measurements and use a strip cutter or appropriate tools to achieve a smooth cut that enhances your project’s lighting effect.

Final Thoughts on Common Mistakes in Measuring and Cutting Techniques

In conclusion, cutting LED light strips requires precise execution and attention to detail to ensure the functionality and aesthetics of the lighting are maintained. One critical mistake to avoid is cutting outside the designated cutting points, which are clearly marked on the strips. These points are specifically designed to allow for a safe cut without damaging the electrical circuitry within the strip. Cutting elsewhere can lead to shorts and render sections of the strip unusable, resulting in wasted materials and increased costs. Additionally, it’s essential to use the right tools, such as a sharp pair of scissors or a knife, to ensure a clean, straight cut. Jagged or angled cuts can compromise the integrity of the LED strip, leading to poor connections and inconsistent lighting.

Furthermore, it’s imperative not to overlook the importance of planning and measuring the area where the LED strip will be installed before making any cuts. This planning ensures that the light strip fits perfectly in the desired space without unnecessary splicing or extensions that can affect the uniformity of the lighting. Another common mistake is neglecting to test the strip’s functionality after cutting and before installation. This step is crucial to confirm that all sections of the strip are fully operational and that no damage occurred during the cutting process. By avoiding these common pitfalls, DIY enthusiasts and professionals alike can successfully customize LED light strips to fit any space, enhancing the ambiance with efficient, evenly distributed light that adds both value and beauty to the area.

5 Mistakes To Avoid When Cutting LED Light Strips | Understanding the Importance of Proper Measurement

Proper measurement plays a critical role in ensuring successful installation when cutting LED light strips. One of the most common 5 mistakes to avoid when cutting LED light strips is not taking precise measurements, leading to uneven cuts that can detract from the overall light installation. An accurate cutting line is essential for creating clean, functional cuts that enhance both decorative and task lighting. Using the right tools, such as a sharp knife or general-purpose scissors, can make all the difference in achieving perfect cuts and maintaining the integrity of the strip lights. Mistakes in color temperature and design can transform vibrant accent lighting into a dim or useless LED strip, affecting the ambiance of a space. Taking the time to mark your cut lines and ensuring a stable cutting environment will minimize the risk of errors that can result in wasted materials and increased project frustration.

5 Mistakes to Avoid When Cutting LED Light Strips | Tools for Accurate Measurements

Accurate measurements are crucial for a successful LED strip installation and can prevent common pitfalls. Using the wrong tools, like a butter knife or inadequate scissors, can lead to uneven cuts, compromising the integrity of your LED lighting. A precise cut ensures that each segment functions correctly and maintains its brightness, allowing for optimal light diffusion across your space. Color temperature mistakes and misalignment may arise if the cutting isn’t handled properly, causing strips to appear dull or uncoordinated.

Employing the right tools is essential for achieving the desired results. Selecting high-quality cutters designed specifically for LED strips can make the actual cutting process smoother and more effective. Dimmers and other features can enhance the light style and ambience, but none of that matters if the cut pieces do not fit as intended. A clean surface and proper techniques, such as marking cut lines accurately, will greatly reduce the chances of creating an unusable LED strip. Having spare strips on hand can be a wise move to mitigate any trim mishaps.

Techniques to Ensure Precision

Achieving precision while cutting LED light strips significantly enhances their functionality. A common pitfall arises from not recognizing where to make the first cut, often leading to color mistakes or improper lengths for accent lights. Accurately marking spots along the strip can prevent unnecessary trimming. Using the right knife is crucial for making clean cuts, ensuring the integrity of small LEDs remains intact. Proper tools, such as nearby scissors or a sharp utility knife, provide the necessary sharpness to get through the strip without damaging the circuitry, allowing for optimal beam of light and avoiding the creation of useless, non-functional segments.

Effective cutting techniques also involve understanding the design patterns inherent in the strip lights. Many LED strips come with predefined cut requirements that highlight areas for optimal chopping. Recognizing these sections allows for a smoother flow in your decorative lighting solution, whether for cabinet lights or full-room light applications. Each strip could require different handling, especially at sharp turns or in designs with bends. Incorporating electrical safety measures during the process is essential. Care should be taken to avoid creating a hitlights strip that flickers or fails due to improper sealing or cuts, which could render the entire set of lights novel and less effective.

Identifying Appropriate Cutting Locations

Properly identifying cutting locations on LED light strips is crucial to avoid common pitfalls. The 5 Mistakes to Avoid When Cutting LED Light Strips often stem from poor decision-making regarding where to make cuts. For instance, cutting in the wrong section could render a portion of the strip useless, leading to frustration and wasted resources. Marks should be made at designated cutting points, typically indicated by copper pads or along the designated cutting lines. This ensures that both the strip lights’ functionality and design remain intact. Strips push the boundaries of home lighting by allowing for custom configurations, whether one seeks candlelight warmth or the high brightness of white lights. Knowing where to cut prevents issues with dimming or malfunction, ensuring your strip lights can shine brightly, even when creating preprogrammed colors or fixed beams with products like Hitlights premium.

Recognizing Design Patterns

Understanding design patterns in LED light strips is essential to avoid pitfalls that can render them useless. Many people overlook the specific segments designed for cutting, leading to mistakes that compromise the functionality of the light. For instance, cutting outside of the designated areas can disrupt the filling light effect, resulting in old strips that fail to deliver good lighting. An informed approach can significantly enhance the lighting experience with brighter bulbs and better overall design.

Patterns in LED strip lights often indicate where to make a single cut for multiple strips, ensuring optimal performance. Recognizing these patterns prevents the common strip light pitfall of cutting in the wrong place, which could leave you with a dowell lighting system that doesn’t shine as intended. A well-executed cut according to the design can transform your project, allowing you to effectively light up spaces. To learn more about how to avoid these mistakes, explore the 5 Mistakes to Avoid When Cutting LED Light Strips mentioned at dowelllights.com.

Marking Your Cut Lines

Properly marking your cut lines is crucial to avoid the common pitfalls associated with LED light strips. Many people encounter the 5 mistakes to avoid when cutting LED light strips due to insufficient preparation. A well-defined cut line ensures that you have a straight edge for your extrusions. Without clear markings, you risk creating a led strip useless for your intended design. Strip lights could become compromised if cut incorrectly, leading to uneven lighting and wasted materials.

Taking time to accurately mark the cut line contributes to a seamless installation. Relying on visual estimations often leads to inaccuracies. Utilizing a measuring tool can enhance precision and help prevent your cut strip from becoming a source of frustration. A carefully planned approach allows the light on your installation to shine bright, avoiding the mistakes that could make your led strip doesn’t meet expectations.

Selecting the Right Tools for Your Project

Choosing the right tools for your project significantly impacts your overall success. The correct equipment can help ensure precise cuts and prevent the common pitfalls outlined in the 5 Mistakes to Avoid When Cutting LED Light Strips. Tools designed specifically for strip lights novel can elevate your crafting experience, allowing you to achieve a clean finish. Poor-quality tools might lead to uneven cuts or damage, which could—wow—sabotage the integrity of your strip lights. Investing in high-quality cutting tools will not only enhance the aesthetics of your project but also extend the longevity of your lighting solutions.

Recommended Cutting Tools

Choosing the right cutting tools is essential to avoid mishaps while working with LED strip lights. Commonly, craft scissors or utility knives are preferred for their precision. Avoid using dull tools, as they can lead to jagged edges or uneven cuts, increasing the risk of damage to the strip lights. Remember the key points from the 5 Mistakes to Avoid When Cutting LED Light Strips to ensure a clean and effective job.

For more intricate designs or lengthy cuts, investing in specialized LED strip cutting tools can enhance accuracy. These tools often feature straight edges or guides to help maintain a steady hand. Ensuring the right tools are on hand can significantly reduce the likelihood of errors. Keep in mind the insights from the 5 Mistakes to Avoid When Cutting LED Light Strips to make your project a success.

Importance of Quality Tools

Using quality tools is essential for achieving the best results with LED light strips. The right tools ensure clean cuts and precise measurements, which can significantly diminish the chances of errors. This is particularly important to note within the context of the 5 Mistakes to Avoid When Cutting LED Light Strips, as poor-quality tools can lead to unnecessary complications. Investing in reliable equipment can make the difference between a successful project and one that becomes frustrating.

Quality tools play a vital role in enhancing the overall efficiency of your cutting process. Strip lights could be easily damaged or rendered unusable if not handled with the right instruments. Understanding the 5 Mistakes to Avoid When Cutting LED Light Strips emphasizes the need for proper tools that cater to the specific requirements of LED installations. By prioritizing tool quality, you set yourself up for a smoother and more rewarding DIY experience.

Sealing the Cut Ends Effectively

Sealing the cut ends of your LED light strips is crucial to maintain their functionality and longevity. One of the common 5 Mistakes to Avoid When Cutting LED Light Strips is neglecting to properly seal these exposed ends, which can lead to moisture damage and electrical issues. Using appropriate sealing techniques ensures that your strip lights could maintain optimal performance without interruptions. Best practices for sealing include using heat shrink tubing or silicone sealant, which provide a secure barrier against environmental factors. Properly sealing the cut ends not only enhances safety but also prolongs the life of your LED installations.

Best Practices for Sealing

Sealing the cut ends of LED light strips is crucial to ensure longevity and prevent damage. One of the 5 mistakes to avoid when cutting LED light strips is neglecting to seal these edges properly. Exposed ends can lead to moisture ingress and electrical shorting, ultimately affecting performance. A secure seal not only protects the electronics but also enhances the aesthetic look of the lighting installation.

Applying heat shrink tubing is a highly effective method for sealing cut ends. This technique provides a durable layer that maintains the integrity of the strip lights. Ensuring a snug fit around the cut edges is essential for the seal to hold up over time. Avoid the common pitfall highlighted in the 5 mistakes to avoid when cutting LED light strips by taking the sealing process seriously.

Materials Needed for a Secure Seal

Ensuring a secure seal at the cut ends of LED light strips is crucial for longevity and performance. Common materials include heat shrink tubing, which provides a snug fit around the exposed wires, and silicone sealant, which offers waterproof protection. Avoiding the 5 Mistakes to Avoid When Cutting LED Light Strips can help maintain the integrity of the connections. The right materials ensure that strip lights could remain functional and safe from environmental damage.

Electrical tape is another practical option that can secure cut ends effectively. It is essential to wrap it tightly to prevent moisture ingress and potential short circuits. Choosing high-quality materials is key to preventing issues down the line. By paying attention to these details, you can avoid the pitfalls highlighted in the 5 Mistakes to Avoid When Cutting LED Light Strips, leading to a more reliable lighting solution.